Key features

Eliminate data uncertainty with high-quality seabed imaging

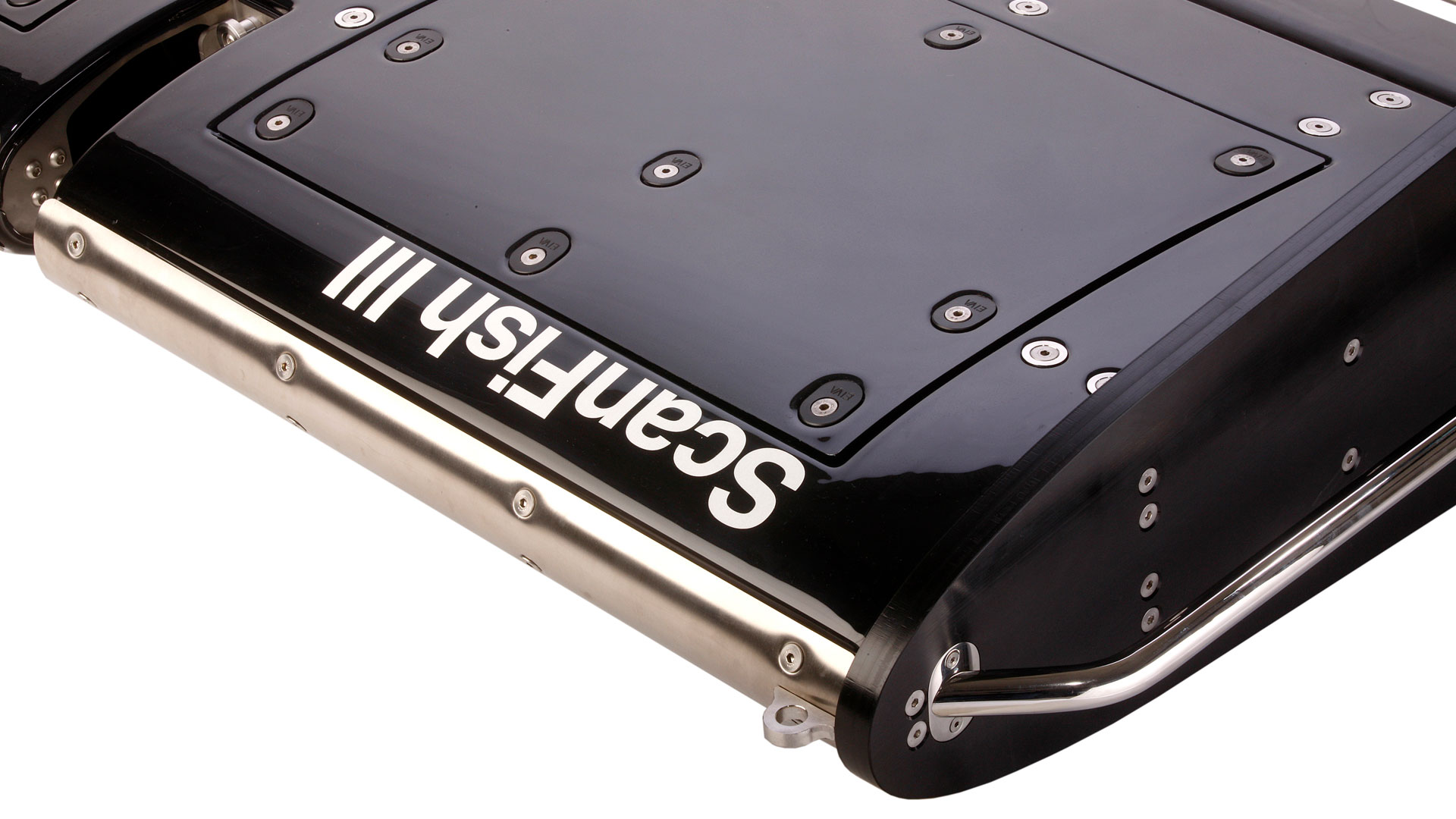

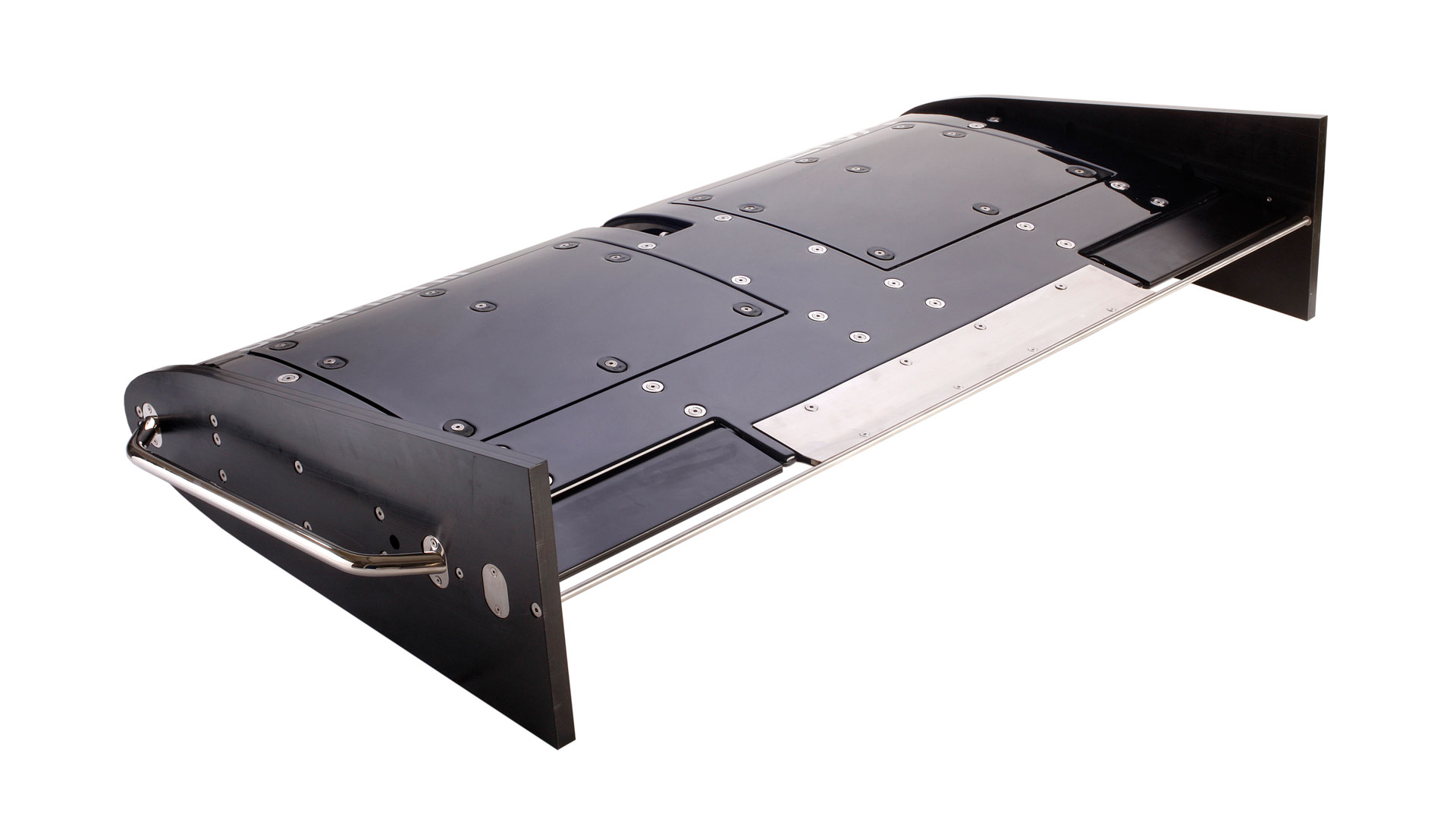

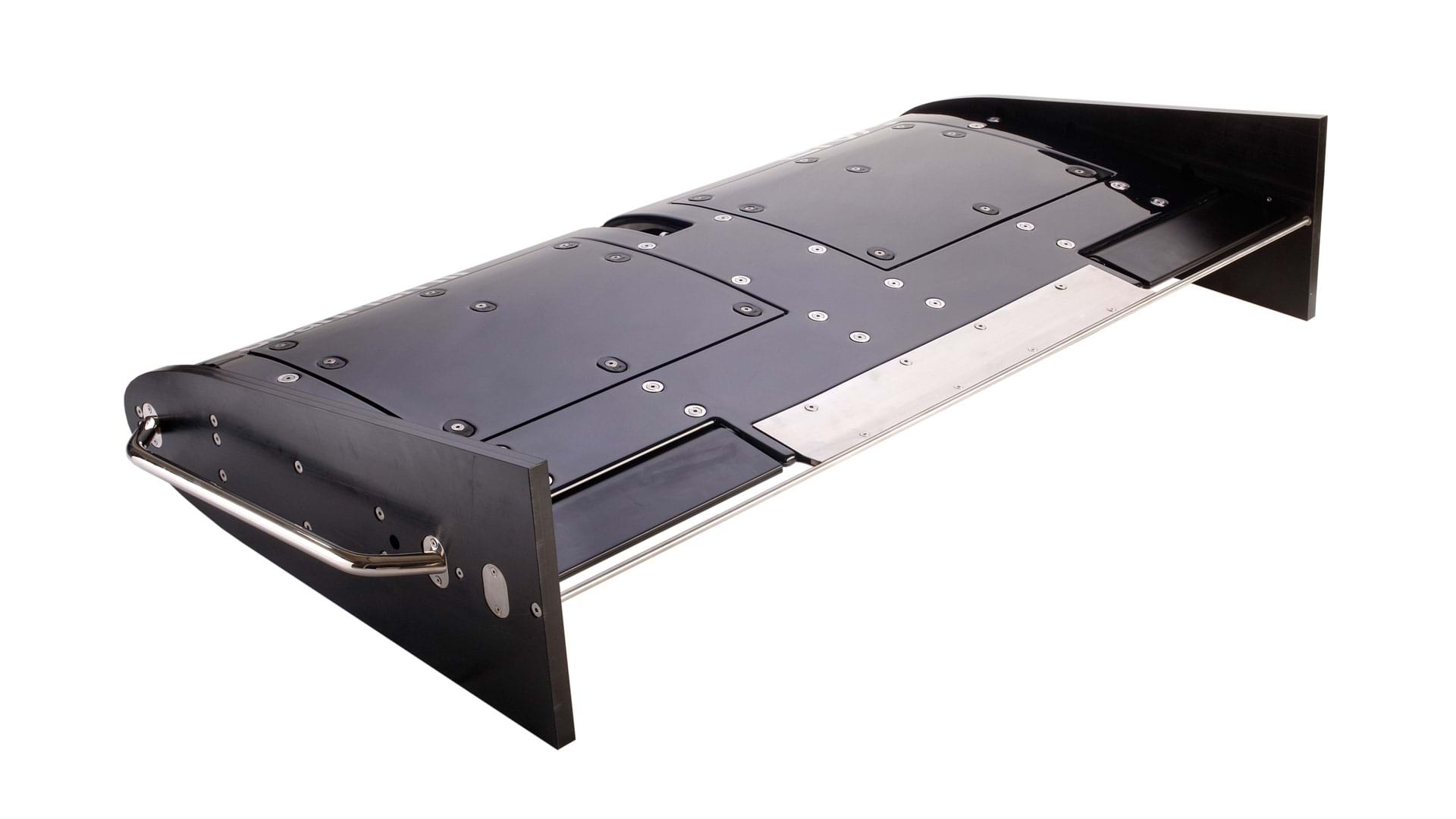

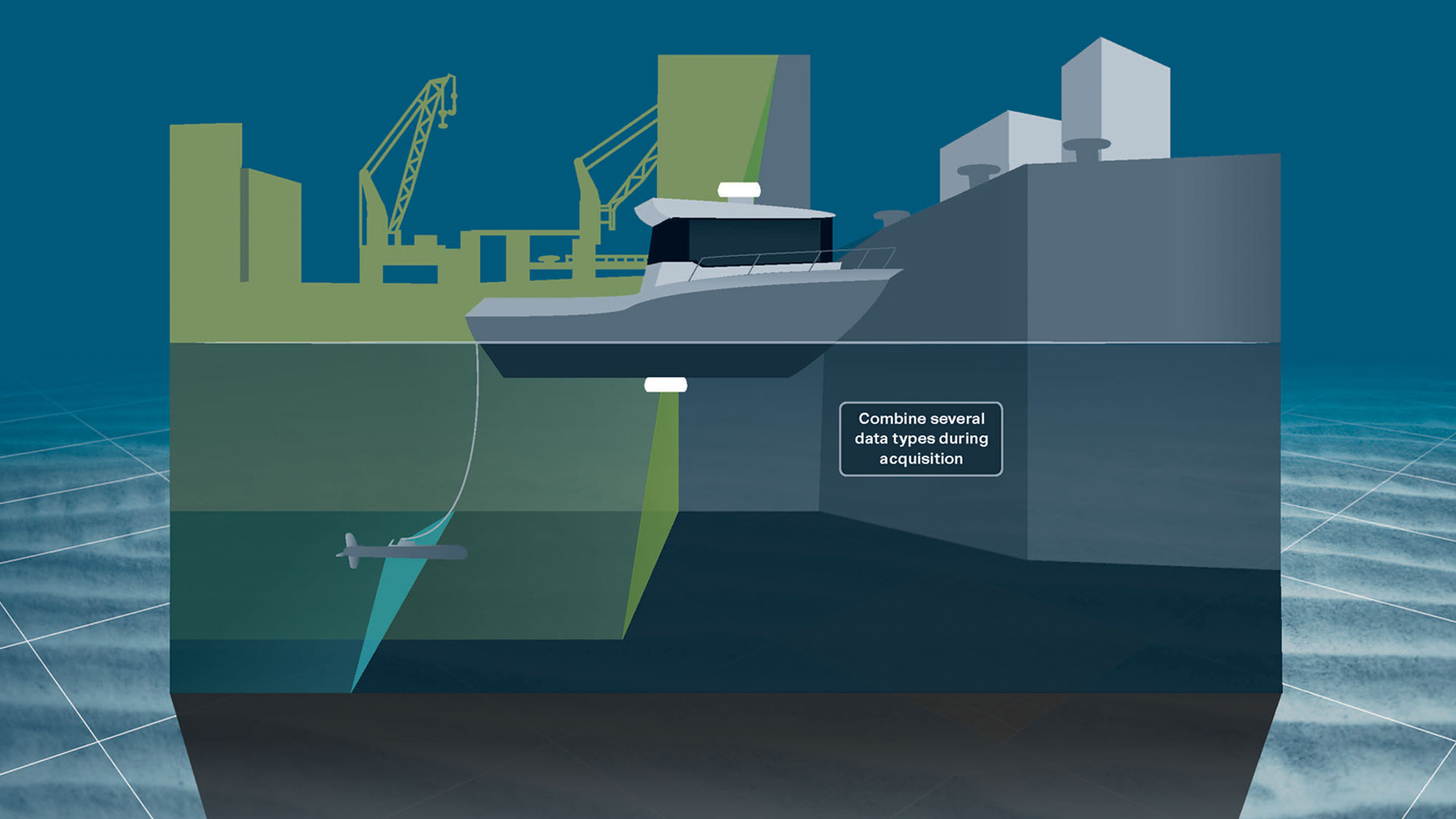

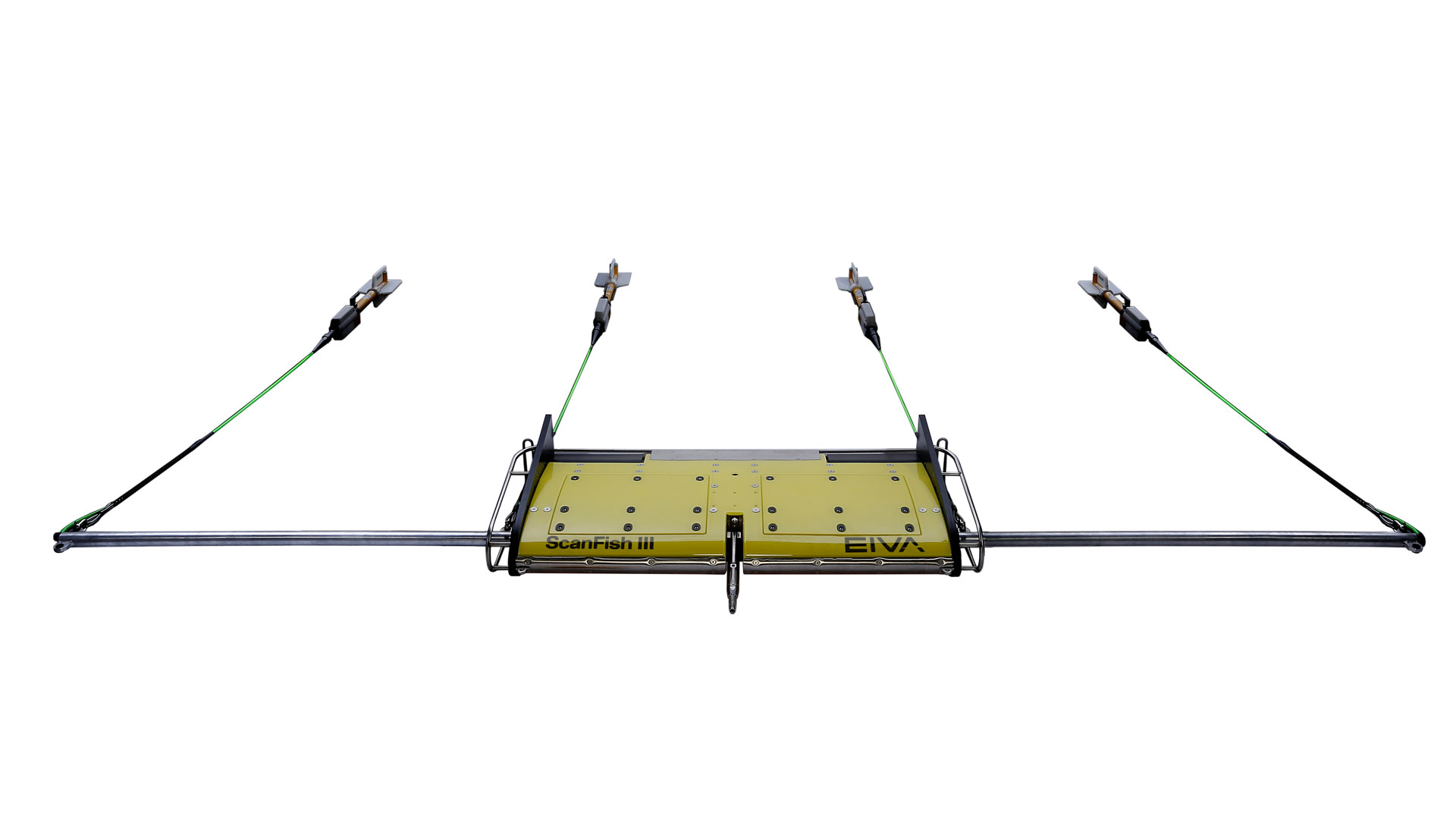

ScanFish Tropheus is a terrain-following ROTV solution for UXO detection.

Eliminate data uncertainty with high-quality seabed imaging

ScanFish Tropheus is a terrain-following ROTV especially designed for UXO detection that eliminates data uncertainty with high-quality seabed imaging

Optimal side-scan sonar positioning

… through an intelligent ROTV functioning as depressorAccurate real-time data

… through continuous data acquisition close to the seabedEfficient operations that do not forgo safety

… through the possibility of using an unmanned vessel to tow the ROTVMonitoring and complete control of the vehicle

… through the user-friendly ScanFish III Flight softwareA long service life

… through quality materialsReduced risk of the ROTV suffering damages

… through robust design and a storage cradle

Continuous acquisition of accurate and comprehensive data

ScanFish Rocio's pattern in the water column is easily adjusted to ensure well-founded results of the survey task at hand.

Continuous acquisition of accurate and comprehensive data

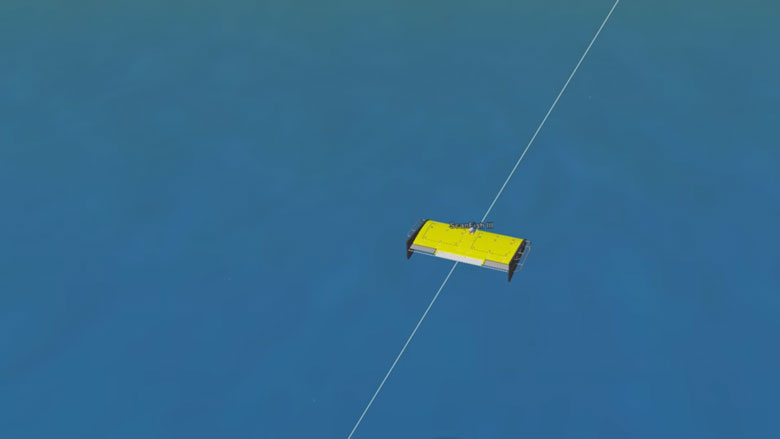

The intelligent control of the ScanFish Tropheus ensures that the ROTV together with the side-scan sonar mounted on the underside maintain a constant, fixed altitude in proportion to the seabed – and far closer than solutions without a depressor.

Add to this a high tow speed of up to 10 knots and the fact that the ScanFish Tropheus allows for continuous data acquisition, you are ensured more accurate and comprehensive data and thus extensively detailed images of any potential UXO targets.

It is possible to set the ScanFish ROTV to operate at a fixed height from the seabed via the ScanFish Flight software

Components and optional extras

The ScanFish Tropheus standard package combined with the optional extras constitute a turn-key UXO solution.

Components and optional extras of the ScanFish Tropheus package

The ScanFish Tropheus standard package combined with the optional extras constitute a turn-key UXO solution

ScanFish Tropheus is available with all the standard components and optional extras that are required to constitute a turn-key UXO solution.

From topside unit to subsea cable termination and multi-ping side-scan sonar, we offer you all the necessary components for an affordable UXO detection solution that will make a great difference to the safety and efficiency of future operations.

Components

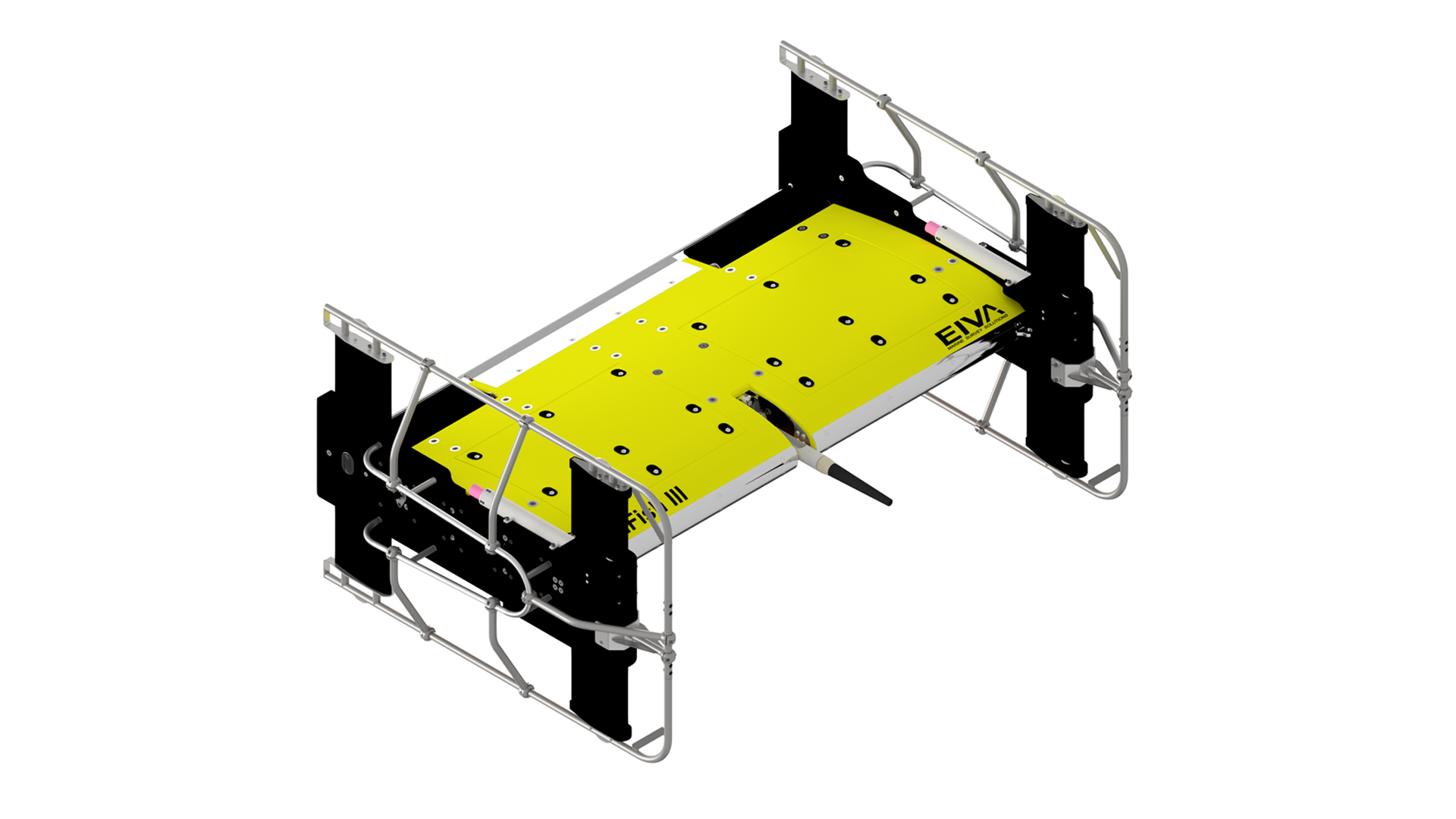

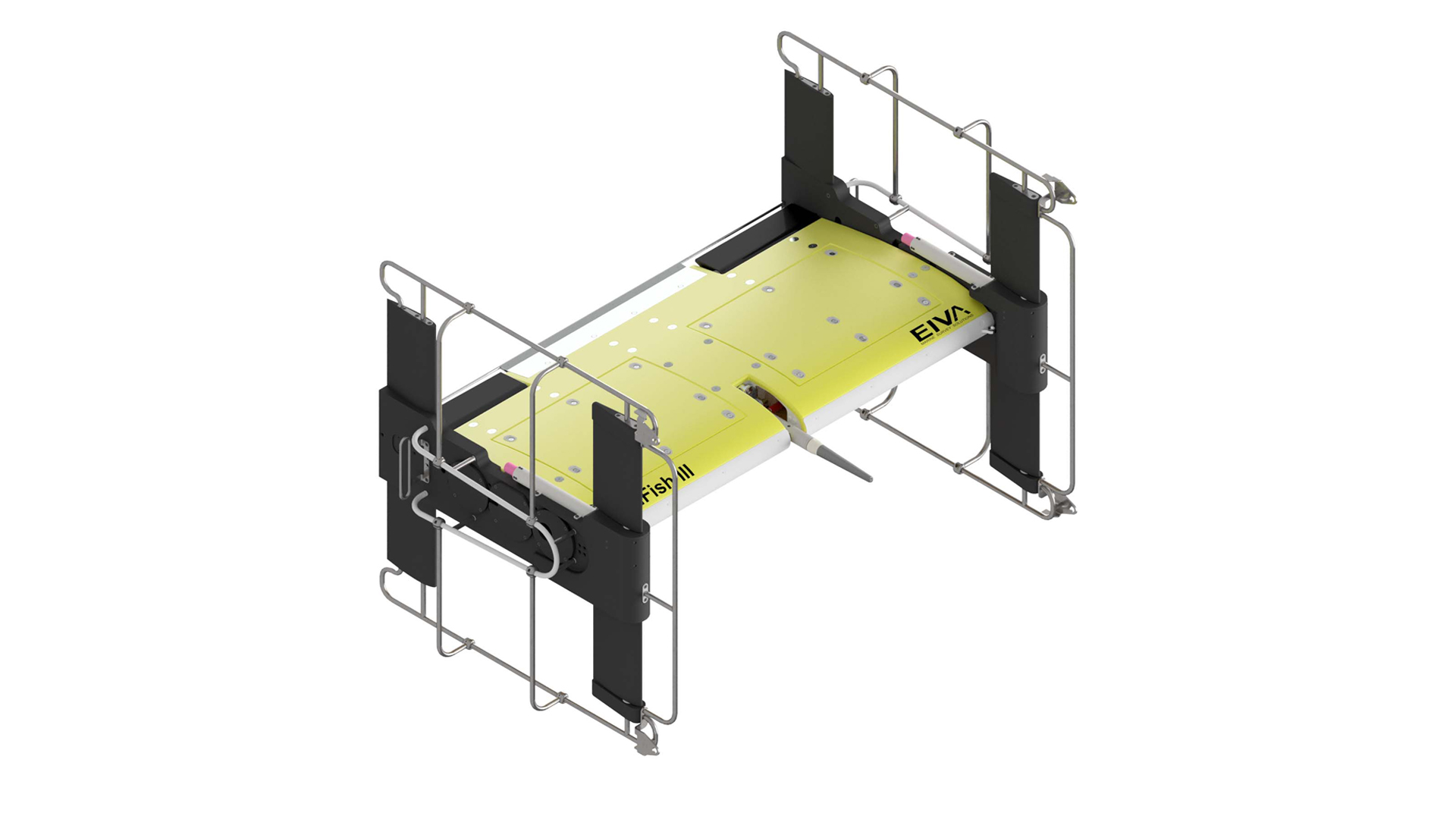

EIVA ScanFish Tropheus

Including altimeter, motion and depth sensorsConnection of side-scan sonar and ROTV

2.5 m power and communications cable, stainless steel towbarSubsea cable termination

Stainless steel tow termination point for mounting on coax cableTopside unit

2U rack unit 19” containing power supply and communications, depth: 35 cm, weight: 7 kgDeck cable

30 mTransport case

Heat-treated, water-resistant plywood, 150 kg, B197xD100xH63 cmCradle

For deck mounting of side-scan sonar and ROTV, incl tarpaulinEIVA ScanFish III Flight software

Data output: cable counter, basic ROTV s tatus (NaviPac format), depth and altimeter (NaviScan format)

Requires minimum (with standard components): dual core Intel, 4 GB RAM, 100 GB 7200rpm HDD, Windows 7 ProOptional extras

3D steering

Hardware solution which introduces horizontal movement control capabilitiesSide-scan sonar

Klein or EdgeTech. Varies according to customer needs and requirementsEIVA NaviPac software

General navigation and ROTV positioning (USBL or cable-layback)EIVA NaviScan software

Sonar acquisition and recording. Recording in EIVA SBD or XTF formatsEIVA NaviScan Target software

Sonar target processing, measurement and classification. XML target databasePinger

RJE International, Inc. ULB-362B, excl tracking

USBL positioning system

EdgeTech ORE BATSROTV cradle

For deck mounting, incl tarpaulinEIVA OceanEnviroTM winch system

PC

Monitor

Tow cable

Choose from a variety of faired cable options to further reduce drag of your ROTV system

User-friendly control and monitoring software solution

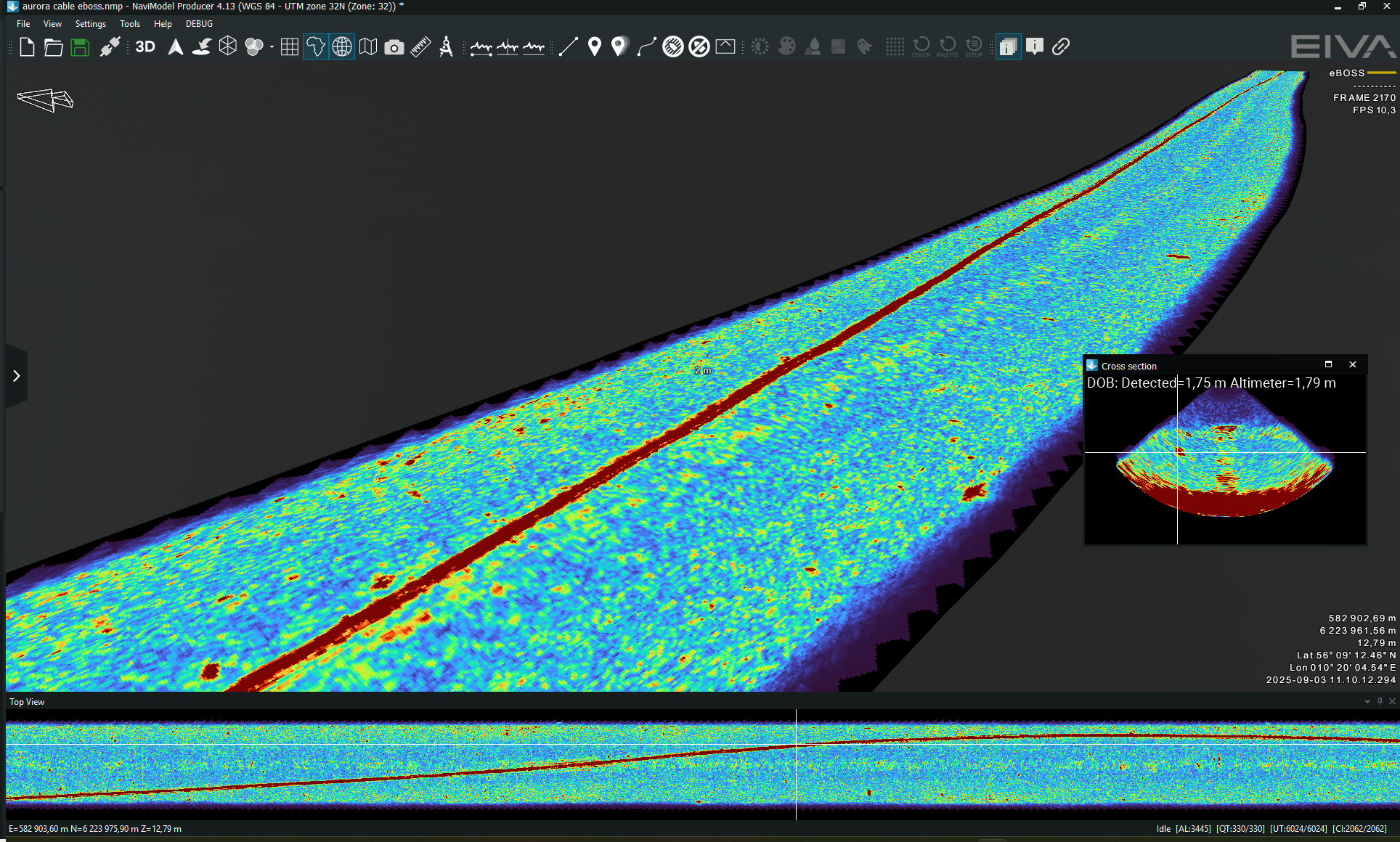

All ScanFish models come with the ScanFish Flight software, which is an easy-to-use software system allowing for control and monitoring of the ROTV.

User-friendly control and monitoring software solution

All ScanFish models come with the ScanFish Flight software, which is an easy-to-use software system allowing for control and monitoring of the ROTV.

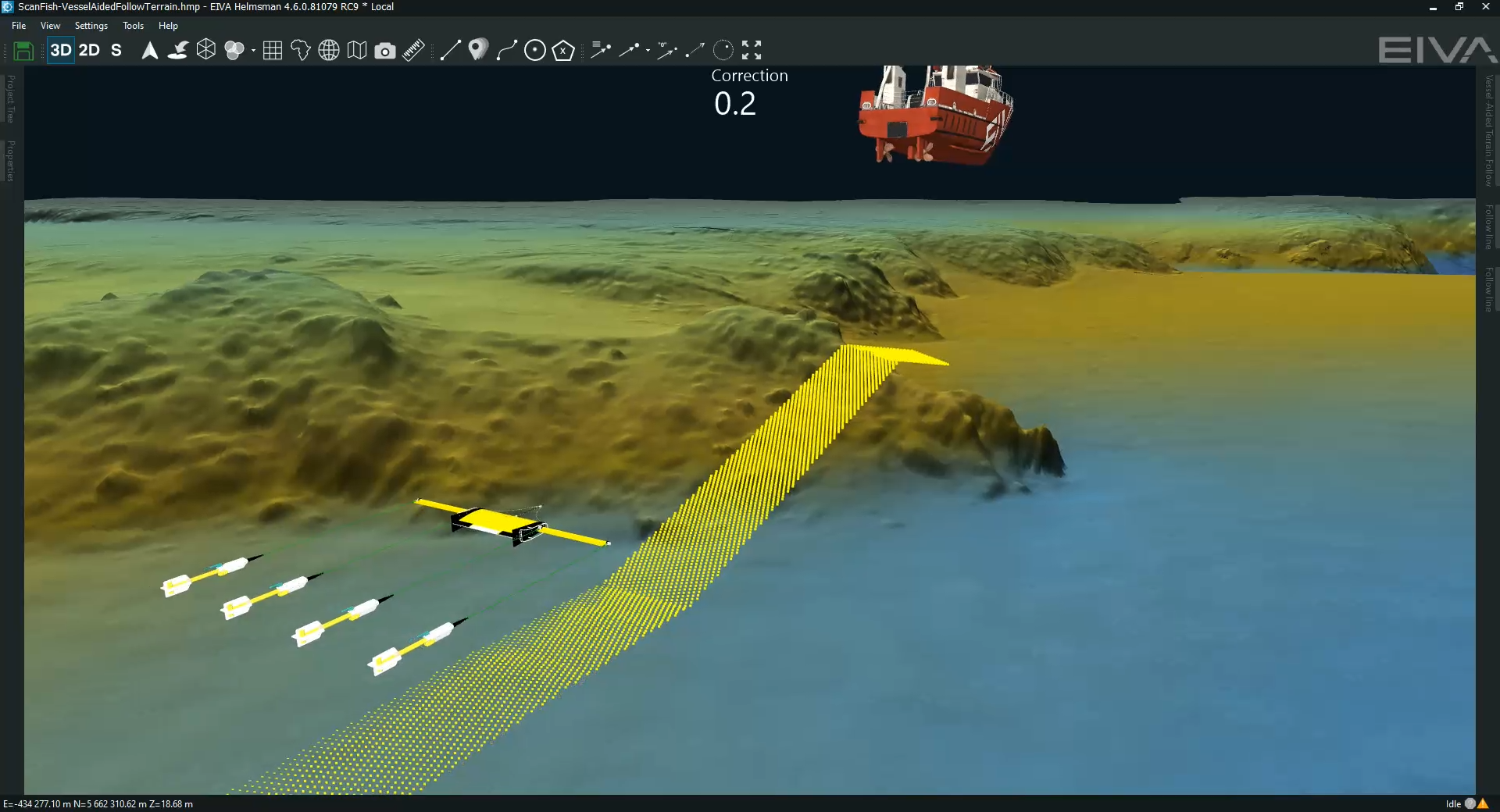

Controlling the ROTV's movements in ScanFish III Flight software

Only a minimum of training is required to prepare the crew to operate the ROTV, which means you will be ready to set sail within a short period of time. Moreover, there is no risk of wasting time on difficulties resulting from a complicated software user interface.

Via the intuitive interface of ScanFish Flight, you are in complete control of the position of the ROTV by defining its height compared to the seabed. At the same time, you can monitor its position in the water, and an alert panel will warn you of any irregularities.

ScanFish III Flight in action

On-site calibration

A pre-flight feature allows for testing and calibration of the ScanFish ROTV on-site prior to deployment, promising you the highest possible performance and data quality.

Recording of flight data

Acquired ROTV data can be analysed by means of a flight recording feature. It enables you to play back all flights and, for example, quickly locate the cause of any irregularities, thus enhancing the quality of your results and saving survey time.

Automatic control of winch

ScanFish Flight can be set up to control the winch towing the ScanFish ROTV, thereby ensuring an optimal cable length adjusted to the movements of the ROTV. This is especially relevant for the ScanFish Rocio models.

Robust product with a long service life

The practical design of the ScanFish models makes them so robust that they can be deployed in rough weather.

Robust product with a long service life

Quality materials and easily replaced wear parts characterise the ScanFish range and contribute to a high ROI through a long service life

The practical design of the ScanFish models makes them so robust that they can be deployed in rough weather. This saves time as the risk of downtime is vastly reduced. Two side plates with bars, which also function as handles, protect the body and facilitate handling, thus reducing the risks posed to the ROTV in the water and ensuring the safety of the crew during deployment and recovery.

Operator courses: repair, maintenance and practical training

EIVA hosts hardware operator courses delivering you the skills and knowledge you need to ensure you get the most out of you ScanFish ROTV.

Combining hands-on practice with expert guidance and advice.

EIVA hosts ScanFish operator courses designed to deliver participants the skills and knowledge to ensure they get the most out of their EIVA equipment.

Under guidance from our expert engineers, these operator training courses deepen your knowledge and understanding of the ScanFish ROTV, improve your practical operator skills and enhance your technical abilities to service and maintain your ScanFish. Featuring classroom work, technical workshops covering hardware repair and maintenance, as well as practical training at sea, EIVA ScanFish operator courses provide a comprehensive platform for expanding your competences.

If you’re interested in a ScanFish operator training course, reach out to let the EIVA team know. We will update you on upcoming hardware operator courses sailing your way.

What do customers say?

'May I say the course and content were spot on, this coupled with an excellent facility and more importantly very knowledgeable, professional, and friendly people that were experienced does indeed make for a winning combination and I will be recommending this course to my seniors for future staff participation.'

Mark Gordon, Survey Engineer, ScanFish Operator course participant

Avoid obstacles more smoothly than ever

This autopilot flight mode uses your vessel’s echo sounder data as an early warning system to avoid obstacles while keeping sensors stable.

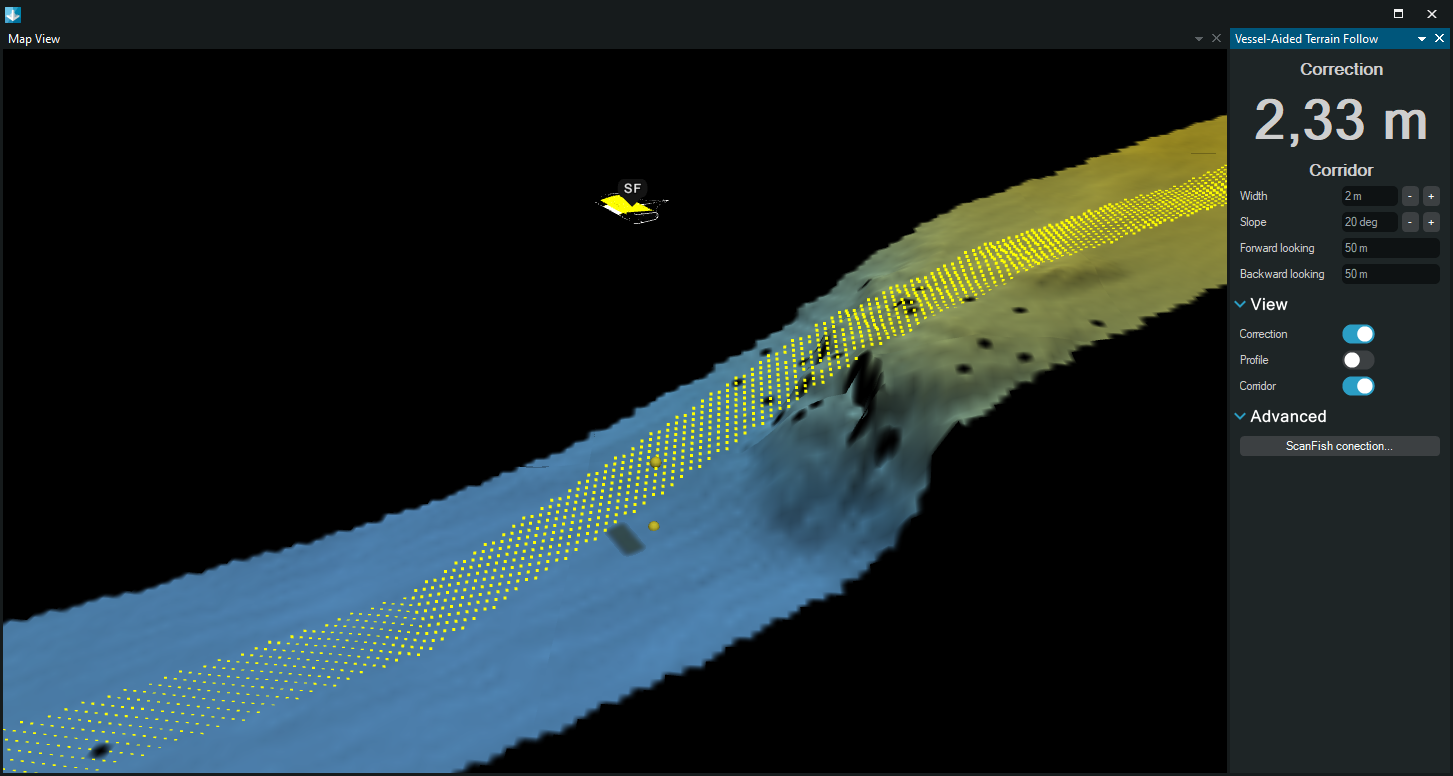

Vessel-Aided Terrain Follow mode

Avoid obstacles more smoothly than ever through automated real-time calculations – this flight mode uses your vessel’s echo sounder data as an early warning system to avoid obstacles while keeping sensors stable.

Video showing the ScanFish Vessel-Aided Terrain Follow mode in action, making the ScanFish avoid steep obstacles on the seabed more smoothly than it would have if it were using only the ScanFish altimeter sensor for obstacle avoidance – thereby achieving stability for optimal sensor performance

The ScanFish Vessel-Aided Terrain Follow mode optimises your vertical runlines based on a DTM (online and/or pre-surveyed). The main advantages are…

It ensures smooth obstacle avoidance, so your data collection isn’t disturbed by any sudden movements of the ROTV, which could otherwise occur if there is a large, steep obstacle, such as a boulder. This is because the altimeter sensor onboard the ScanFish would register the obstacle when closer to it, causing the ScanFish to move quickly out of the way to avoid it. On the other hand, with the Vessel-Aided Terrain Follow mode, the ScanFish can react ahead of time thanks to an early warning from the DTM, and therefore you have the option to make it do avoid obstacles more smoothly over time.

You minimise risks to your ROTV by not only reliably predicting obstacles and avoiding them (as the ScanFish ROTV already does) but also customising how you avoid them, so your ScanFish ROTV’s vertical steering is tailored to your specific ROTV configuration (with this new mode, you can customise the area in which obstacles are avoided and the slope with which the ROTV avoids them.

The area highlighted in yellow is the corridor in which objects are considered relevant obstacles to be avoided using the Vessel-Aided Terrain Follow mode – and the two yellow spheres below the ScanFish model show the correction to the vertical route

Stay safe with a failsafe

This new steering mode is doubly designed to avoid any harm to your ScanFish. The EIVA team has equipped it with a failsafe function for the unlikely case of a malfunction in the setup causing your ScanFish to receive erroneous data from the synthetic altimeter calculated by NaviPac. An error in the synthetic altimeter can occur for example if you are using a pre-surveyed DTM which is outdated, as a new obstacle has appeared since then. In such a case, the priority will always be given to the minimum height registered by the ROTV altimeter mounted on your ScanFish.

Easy integration with your ScanFish ROTV

This automated steering mode is available for all ScanFish systems. In addition to your vessel and any model of ScanFish ROTV, this steering mode uses the following components…

- Multi-beam echo sounder on the vessel which is towing the ScanFish (optional as you can alternatively use pre-surveyed DTMs):

- Acquires seabed data to create a real-time DTM

- NaviSuite Kuda Pro, EIVA’s hydrographic survey software solution (alternatively, if using a pre-surveyed DTM, you can use NaviPac Pro or NaviPac Single User):

- Collects multi-beam echo sounder data and creates a DTM in real time – or displays a historical DTM

- Calculates your ROTV’s optimal vertical route based on the DTM and your settings for obstacle avoidance

- Inputs synthetic altimeter values to your ScanFish Flight software so you follow this route

- Multi-beam echo sounder on the vessel which is towing the ScanFish (optional as you can alternatively use pre-surveyed DTMs):

Specifications

- ROTV DIMENSIONS

- Length

- 0.90 m

- Height

- 0.26 m

- Width

- 1.80 m

- Weight air/water

- 75/0 kg

- Colour

- Black

- PERFORMANCE

- Depth range

- 400 m

- Operational depth

- Up to 400 m – Depends on ScanFish configuration, operation speed and winch configuration – Use of automatic operation modes requires automatic winch control

- Towing speed

- 4-10 kt

- Dive/climb speed

- 0-2 m/sec

- Anti-collision climb

- 3 m/s = 45° at 6 kt

- Vertical position precision

- 0.2 m

- Roll precision

- 0.5°

- Max slope, terrain-following mode

- 20°