To use this site, please enable javascript

To use this site, please enable javascript

The technological development of the maritime industry is moving faster than ever. Staying ahead and thus ensuring maximum gain of the possibilities this development brings, from the beginning, is vital to every organisation involved in operations at sea.

EIVA sees five decisive trends resulting from new and improved technologies. In this and four additional blog items, our CEO, Jeppe Nielsen, will dive into each of these trends in detail.

Author: EIVA CEO Jeppe Nielsen

EIVA was born out of the offshore construction sector in 1978. Through the years, we have expanded our activities and products to cover numerous other sectors of the maritime industry. The nearly 40 years in the business have taught us that the technologies behind the equipment and software in play are intertwined, and that there is an evident synergy inherent in applying these across the numerous sectors evolving around subsea and above water survey and engineering. This includes new trends and the possibilities they bring.

One such trend is the development of sensor technologies such as lasers, used both below and above sea level.

Some 40 years ago, the market saw the first commercial multi-beam echo sounder (MBE), building on the technology of single beam echo sounders for more efficient survey operations and data of higher quality. Since then, the various MBE options on the market have become even more accurate, while at the same time the price of a unit has become more affordable. This means that the technology today is available not just in theory but also in practice to the entire maritime industry.

Where MBE technology builds on the physics of acoustics in water and has been the de facto technology for survey operations, the industry has now also turned to laser sensors. This technology adds new, high-resolution light to the equation of subsea and surface data collection and imaging – at an affordable price.

For some years, airborne lasers have been used for seabed mapping. The positive side to this approach is the high level of speed and coverage. However, it also comes with some limitations to accuracy due to reflection/bending when the signal crosses the water surface as well as limited visibility through water.

More recently, we have seen subsea lasers making their way into the subsea survey/construction discipline as the go-to sensor for high accuracy. Placing the laser below the water surface and thus closer to the seabed or structure being surveyed eliminates the accuracy limitation seen with airborne solutions. Some lasers even provide submillimetre-level resolution. This translates into extremely detailed AUV-/ROV-based surveys – and not just for companies with a large budget for equipment investments.

High-precision lasers are not more expensive than a good MBE, and provide engineers with the detail and precision needed for detecting and assessing damage, developing design and repair plans, and performing maintenance and installations.

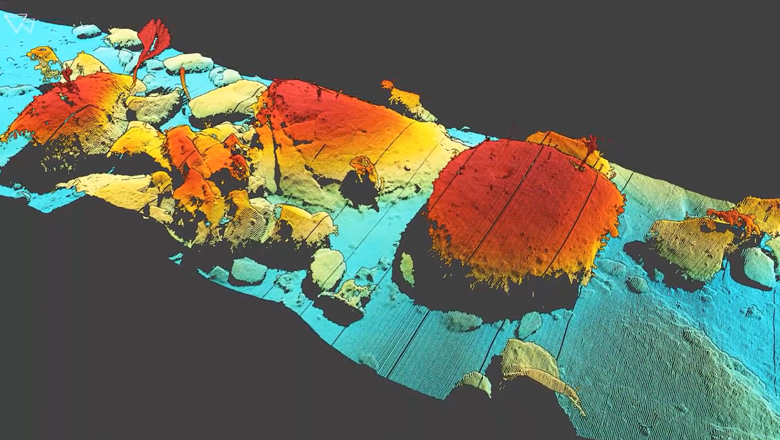

The below video from Sonardyne shows a 3D model made from data collected with a 2G Robotics ULS-500 underwater laser scanner. The survey was made from an ROV and resulted in millimetre accuracy, which is more than sufficient for what is called dynamic metrology. A Sonardyne INS made expensive and time-consuming LBL setups redundant as it ensured sufficient accuracy of the 3D positioning.

3D model of Monterey Canyon. Data obtained by Sonardyne during a deep water survey using 2G Robotics' ULS-500 underwater laser scanner mounted to an ROV to dynamically scan the seabed.

While a laser will capture more detail than a sonar, its range is in turn limited. 2G Robotics have made an excellent article comparing the two technologies and discussing their complementary features in detail, which is worth a read.

Due to laser and MBEs having different strengths, it is often seen that the two are combined for maximum data coverage and detail during survey and inspection operations.

We have met offshore and shallow water survey and construction professionals with quite impressive subsea – and surface – sensor survey spreads, making use of this possibility. These setups include lasers combined with other sensors such as quad-head MBEs, gap-filler sonars, and high-resolution imagery – often collecting data at high speeds. Examples of these are the marine survey specialist MMT’s Surveyor Interceptor underwater ROV and the service and technology provider DeepOceans’ SUPERIOR ROV.

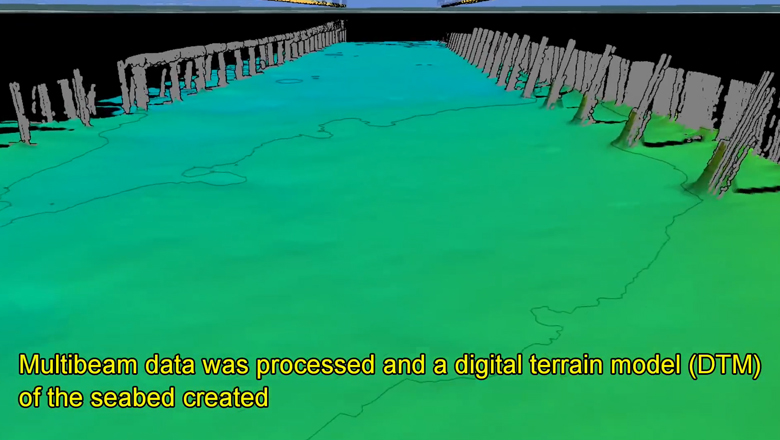

For shallow water surveys, including coastal and harbour inspections, it is becoming the norm to combine sidescan or MBE data with data collected with terrestrial (above-water) vessel-mounted LiDAR sensors, especially as it has become possible to collect multiple data types such as these simultaneously. The result is not only a far more detailed overview but also vast reductions in the time spent on the survey and processing. And, again, better accuracy than seen with data collected via airborne lasers.

Harbour survey data collected with a Merlin LiDAR and Reson SeaBat 7125 multi-beam echo sounder visualised in EIVA NaviSuite NaviModel

We did some testing in 2016, and, not surprisingly, the nature of a laser means that they like working in the dark. Consequently, subsea lasers run into problems when used for shallow water surveys, at least if they are carried out after sunrise / before sunset.

Ambient light as well as water clarity are some of the parameters that have proven to cause enough issues for the laser not be a feasible solution for this type of survey – for now.

This, however, should not take away the status of lasers as a very reliable and cost-effective solution for high-resolution surveys in other environments. The benefits of working with (sub)millimetre level resolutions are obvious and we’re only seeing the beginning of this technology’s possibilities.