To use this site, please enable javascript

To use this site, please enable javascript

When the EIVA ScanFish remotely operated towed vehicle was designed in 2012, the motors in the active flaps were based on an oil-filled design, where the oil would even out the outside pressure. In 2016, we set out to re-design the motor housing – both to get rid of the oil for environmental reasons, and to provide a design with very high mean time between failures (MTBF).

Now, two years since the launch of the current final design medio 2017, and 250 motor units later, we can measure the actual failure rates and are very satisfied with what we see.

Designing a high-pressure watertight motor housing with quickly rotating axels is not a simple mechanical design in itself – making it work continuously for even thousands of hours takes the problem to another level.

First, our mechanical engineering team made a number of designs with various seal types using the best design and simulation tools available. The team then produced prototype versions of each of these designs, selecting high-quality seals. Each prototype was tested in our in-house pressure tanks while working continuously under varying pressure and axel loads for several weeks, after which they were taken apart, and carefully inspected for any trace of water injections or other issues. This process was repeated for more than six months, narrowing the number of designs down to a few designs to move forward with.

These successful prototypes were tested at sea with our test ScanFish system to ensure satisfactory real-life performance. A 0-series was made in the spring of 2017 and put to test on selected real ScanFish systems for three months, after which the design was refined and officially released medio 2017.

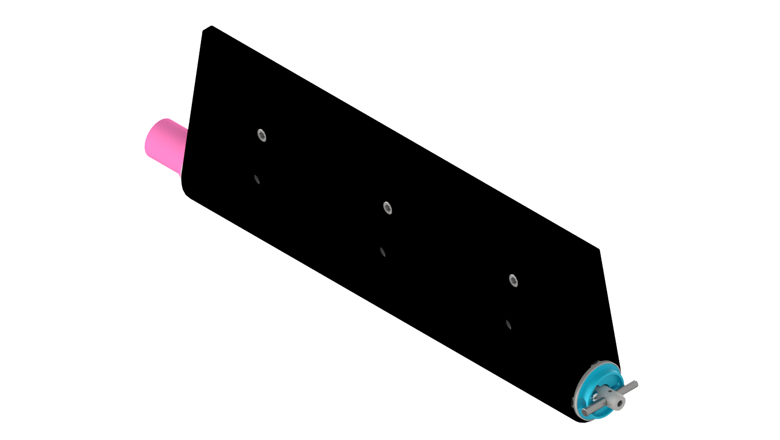

Cross section view of ScanFish ROTV oil-free 2D flap motor: with the motor controller, motor, gear and the new sealing cap

Overall, we have seen issues with 1.2% (ie 3 motors) of the total 250 motors produced since medio 2017 having an issue and none in the ~90 produced since December 2018. Of the three damaged, one was a non-warranty case, with the motor sustaining exterior physical damage beyond repair, the other two were repairable under warranty due to internal gear/motor defects. Moreover, none of the issues seen were related to the new design or related to leak/water ingress.

We kept a couple of units of the successful design running in our pressure tanks, so that we have an in-house measurement of more than 12 months of continuous 24/7 operation to see the condition of seals etc after around 10,000 hours of use and be able to provide MTBF guidance for longer periods. The same units will be re-assembled, and run for a year further to see how they perform after 20,000 hours. It is worth noting that very few, if any, of our ScanFish experience this heavy continued runtime at sea, nevertheless we see this as a way of ensuring the ScanFish’s endurance.

Standard ScanFish ROTV 2D flap motor

Despite having a seemingly long lifespan, the seals used in the motor design are a wearing part, so in order to maximise the lifetime of the motors, we do recommend that motors are serviced at regular intervals, where the (relatively low cost) seals are replaced and the interior of the motor is inspected. A service of a motor in EIVA’s workshop is EUR 700 compared to the price of a new motor of EUR 6,245.

Please note that motors with the oil-free design can replace motors of the older oil-filled design without modifications to the ScanFish.

You can purchase new flaps in our webshop. Please also feel free to reach out to learn more – and check the Recap of EIVA Days Denmark, where the ScanFish was of course on the demo agenda.