How EIVA’s wave buoys ensure safe sailing during the construction of a bridge in unpredictably changing waters

When the current conditions challenge construction

In Denmark, over the Storstrømmen strait, a bridge is being built to connect Scandinavia and Germany with a high-speed rail link. The name ’Storstrøm’ translates to big current – with good reason. The strong current there means the conditions in this strait are rarely optimal for the construction of the bridge.

The first step of the bridge’s construction is laying out the foundation for the bridge on the seabed. When placing the large concrete blocks which make up the foundation, it is important that the waters are calm enough that the blocks can be placed precisely when dropped. SBJV, the Italian joint venture building the bridge, needed to know when the conditions were calm enough to do this. They recruited the help of WSP, a sustainable construction consultancy, to solve this challenge.

An illustration of how it looks when SBJV precisely lowers one of the concrete foundation blocks – video courtesy of Vejdirektoratet

A floating solution measuring current, wave and wind

In order to take advantage of the rare time slots when the conditions are right for placing the foundational blocks of the bridge, WSP identified that they would need to constantly monitor the current, wave and wind conditions in the area where the bridge is to be built.

To monitor these conditions, they needed a robust buoy equipped with the right sensors, and which facilitates remote monitoring of the data collected – and EIVA delivered this: our standard wave buoy, the ToughBoy Panchax 1.2, with the met station option.

The ToughBoy is a wave buoy with low service and communication costs, which the EIVA team tailors with the sensors the customer requires. In this case, the Vaisala WXT weather transmitter was added, on top of the standard wave sensor and Teledyne Workhorse Monitor ADCP (acoustic Doppler current profiler). The met station for weather monitoring is among the common options for tailoring the ToughBoy, but the team is happy to mount other types of sensors too.

Placing the buoy in the waters of Storstrømmen

Monitoring from afar

Since the goal is to know what the conditions in the strait are in real time, it is important that the solution sends the collected data to the shore constantly. The alternative would be to sail out to the buoy and gather the data on a USB stick, which would not only be time-consuming, it would defeat the purpose of the buoy, which is to know the conditions before sailing out.

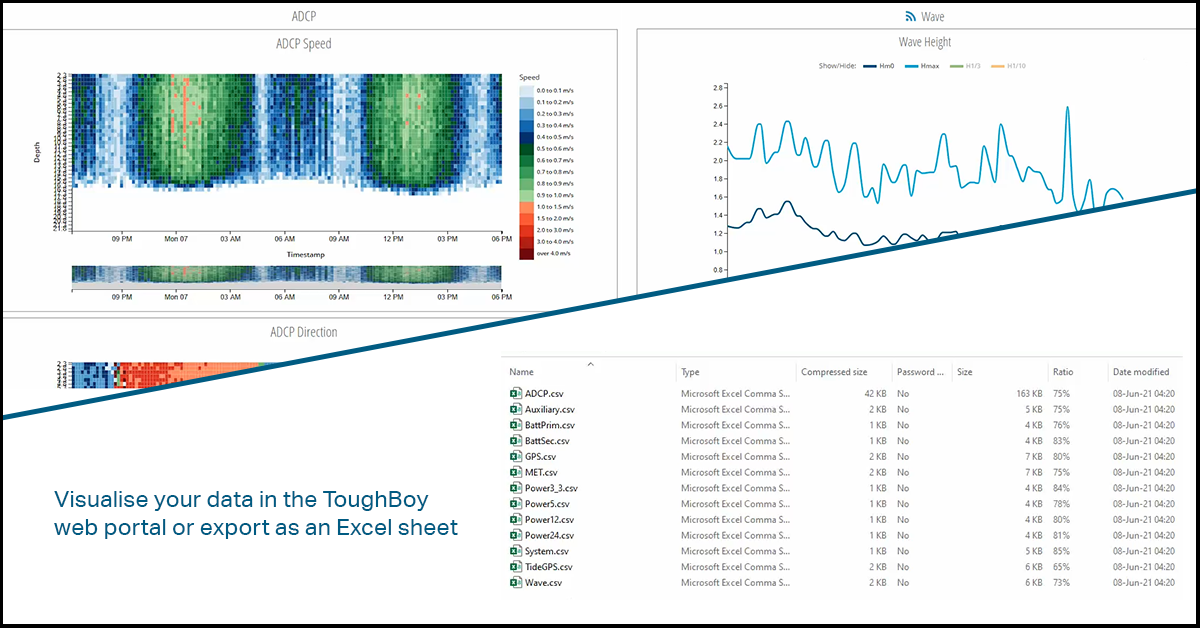

With purchase of a ToughBoy, EIVA includes access to a web portal, ToughBoy Onshore, where customers can view the data their buoy collects, from wherever they are. The data is available to the customer and is stored in the EIVA server as a backup.

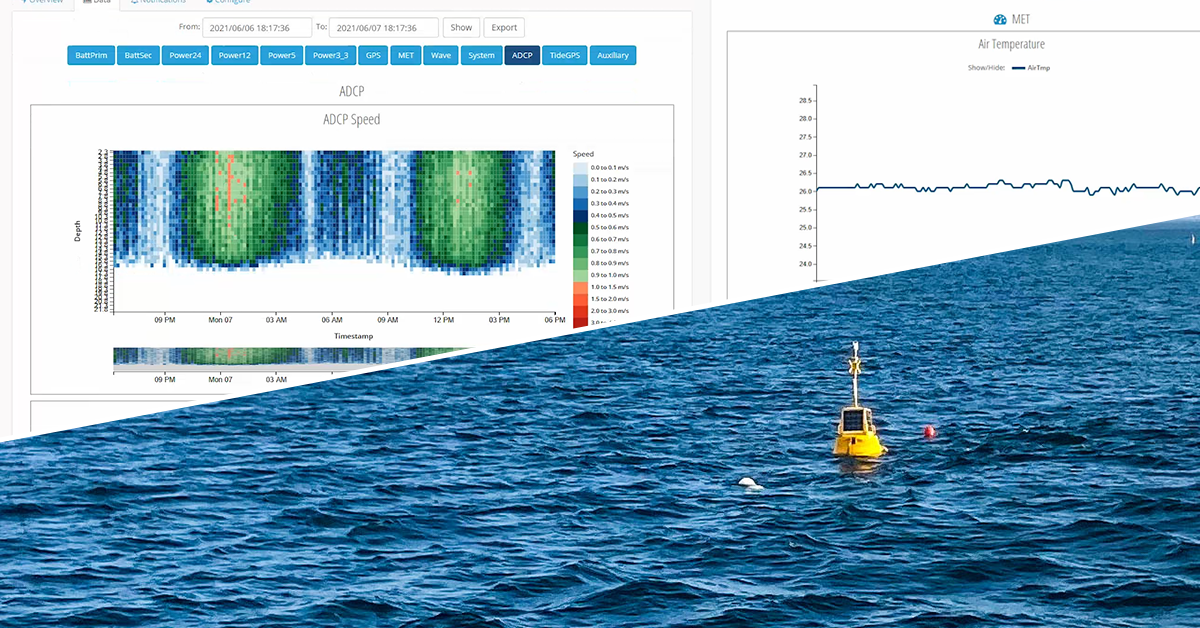

Viewing wave buoy data in the EIVA ToughBoy Onshore web portal

Two buoys are better than one

No matter how good a solution is, accidents can happen. WSP wanted to be prepared in case anything happened to put the buoy out of action, such as a collision. To ensure that the monitoring would be uninterrupted, WSP bought a safety backup – a second ToughBoy.

Another possible option for a backup is to buy a reserve buoy, which is stored at EIVA headquarters and immediately shipped out if there is a problem with the one in use. That is what another customer, wpd, has done.

Reliable results from the ToughBoy

In the spring of 2020, the ToughBoy was put into action. It has operated consistently ever since, ensuring the construction team could sail out in safe conditions.

'Even without being a technician, we found the ToughBoy was easy to assemble and use. We pretty much didn’t have to do anything more than put it in the water.' – Ole Smith, WSP

Watch the process of assembling and deploying a ToughBoy in this video

Some like to DIY their data view

While the data can be viewed in the EIVA web portal, ToughBoy Onshore, it can alternatively be used in an external system. This is done by setting it up to export from EIVA’s system in real time.

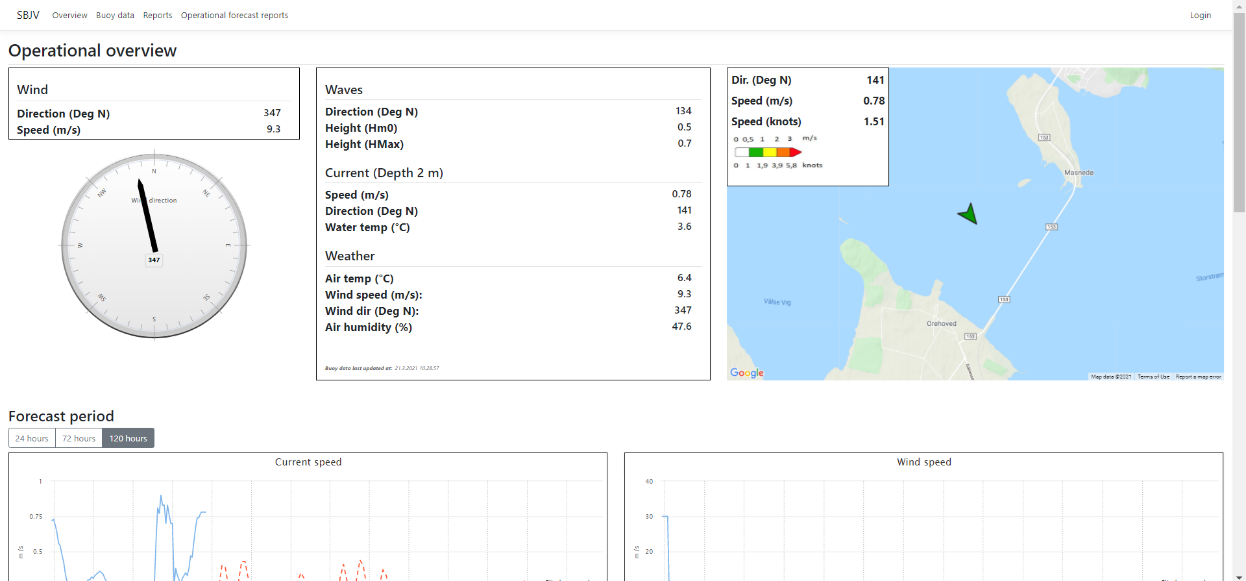

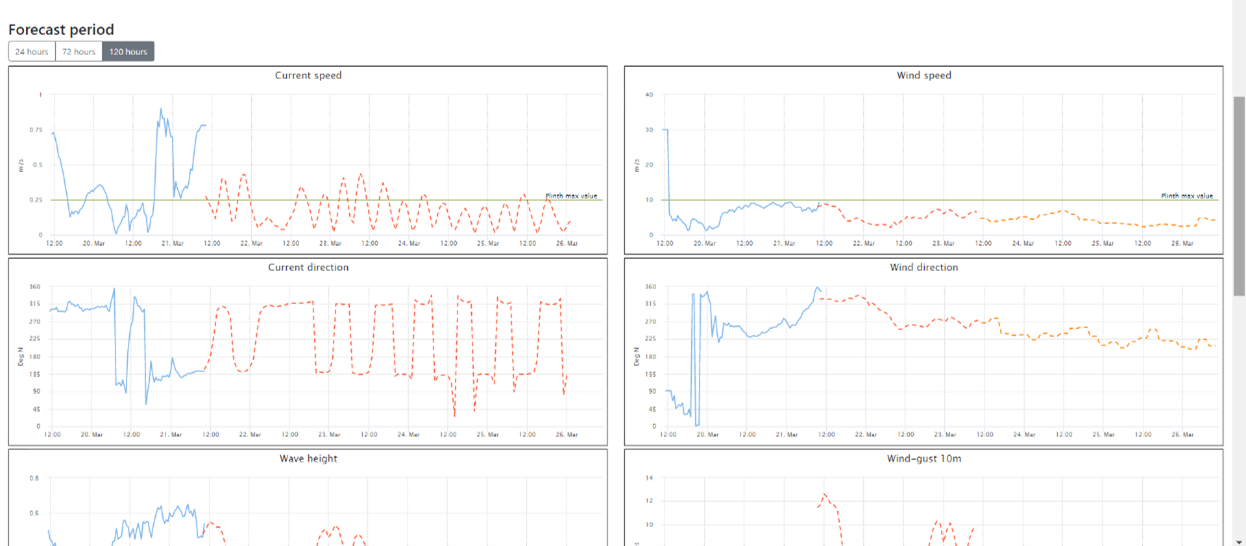

WSP chose to export the data into their own platform, which shows the data from the ToughBoy in combination with predictions from DMI, the Danish meteorological institute. It displays an hour-by-hour overview of when SBJV can or cannot operate according to predictions, as well as generating documentation files of past conditions.

Before sailing out at the times when the predictions say that SBJV will be able to operate, they first check the data from the ToughBoy, to see whether the predictions fit with reality. This combination of predictions and measured data lets SBJV take full advantage of the times when the conditions are right.

The main view of the platform in which WSP displays data from the ToughBoy

Farther down, the forecast (orange dotted line) and the actual measured data from the ToughBoy (blue line) is displayed

Products in play

ToughBoy Panchax wave buoy with low cost of ownership

- Workhorse Monitor ADCP from Teledyne RD Instruments

WXT weather transmitter met station from Vaisala

Facts and figures

- The buoy was put into action in the spring of 2020

- It has measured current speeds of over 1 m/s

- The new Storstrøm bridge will be approximately 4 km long

- 45 cement blocks will be placed to make up the foundation of the bridge

- The bridge is expected to be finished in 2025